COLD-DRAWING

In the years that marked the transition from the nineteenth to the twentieth century, an unprecedented boost in industrialisation occurred, particularly in the regions of northern Italy. The Lombard landscape was dominated by small industry, but the innovations that were then introduced would revolutionise working methods. One of the branches of metallurgy that developed was drawing. Nowadays, the cutting-edge technologies have been introduced in the Lucefin Group plants have seen the company become a world leader in drawn products.

What do we mean by drawing?

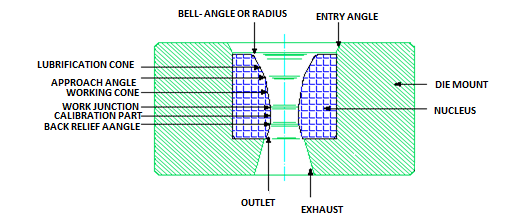

Drawing is a cold plastic deformation operation which uses tensile forces to stretch metal. After the hot-rolled material (bars or coils) is subjected to chemical or mechanical pickling to remove the surface oxide layer, it is forced to pass through a die to reduce its diameter and increase its length using a drawing force.

The die has a section lower than that of the starting material so the pulling force must overcome the yield strength of the material without breaking, in order to permanently deform it to the shape and size set.

Drawing is usually done at room temperature and is therefore classified as a cold working process, however it may be performed at elevated temperatures to hot work steel hardness, i.e. high-speed steel at a temperature of about 300°C. In some cases it is hot-melted to give the material specific properties.

Unlike machining with shaving removal (milling, turning, etc.), which involves a significant reduction in weight to obtain the desired size, weight reduction in drawing is minimal because it only concerns the edges of bar ends. ltd catalog The scrap for the “threading” tips and the surface oxide is eliminated from raw materials by sandblasting, and the section limit from laminate to drawn involves an elongation in the drawing direction.

The following table shows how much the material stretches according to the section reduction.

| Calculation for rounds | Calculation for plates/squares | ||||||

| Laminated dimensions in mm | drawn | Laminated dimensions in mm | drawn | ||||

| diameter | length | diameter | height | thickness | length | height | thickness |

| 52 | 11500 | 50 | 47 | 47 | 5600 | 45 | 45 |

| Drawn length | Drawn length | ||||||

| 12438 | 6109 | ||||||

| Reduction ratio | Reduction ratio | ||||||

| 7,5% | 8,3% | ||||||

Drawing allows to obtain a finished product with narrow dimensional tolerances (h11, h9), uniform surfaces, absence of oxides, limited ovalisations, calibrated thicknesses, good roughness (Ra 1,6 – 3,2 μ) and excellent straightness (1.5 – 1 ‰). All these characteristics remain stable and uniform for the entire quantity of a given section put into production.

Control systems are installed on the most modern drawing plants, which guarantee compliance of the product with the required characteristics and ensure its suitability for the intended use.